Our Connectors are manufactured under most stringent quality standards to suite the customers specific requirements. We keep a strict vigil on the quality, right from the entry stage of Raw materials like Nylon Granules & Master Batches to the manufacturing stage till delivery of finished products.

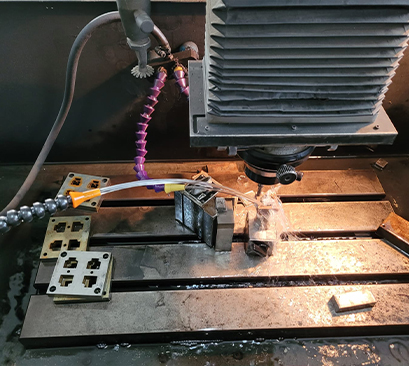

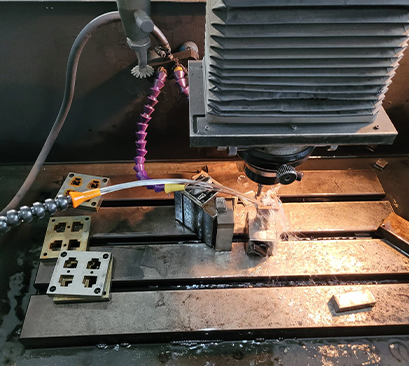

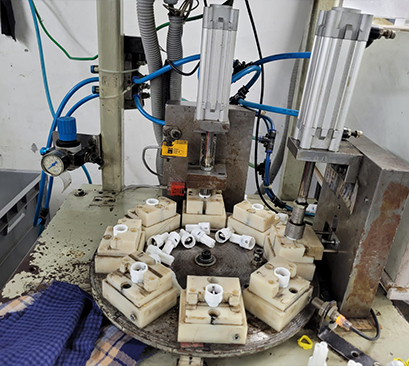

Our products are tested through various Test Lab Equipment’s before dispatching to our customers. All our capabilities are enabled by state-of–the–art technology that further ensures flawless quality and superior finish, when it comes to Connectors.

Our Complete Emphasis is on checking Quality during Manufacturing Process of Connector, which is the best way to ensure quality products. We have 4 Process Inspectors to Check the Quality of Product Online at the Manufacturing stage.

All our products are tested on the parameters of their durability, hardness, Insertion & Back-out force etc. For this purpose, our Quality Control unit is fitted with a range of testing machines and tools to get accurate results.

We strongly believe that the proven quality of our products and our understanding of customer needs have resulted in better productivity. Our direct involvement in manufacturing process and supplies with technical know how assures the best quality products and services.

Our commitment towards quality, service and value has enabled us to achieve preferred supplier status.

Moreover, we have a Test-Lab equipped with sophisticated Machines to ensure better quality of Connectors such as: